Krückemeyer - Ihr Partner für Klebe- & Schleifanwendungen

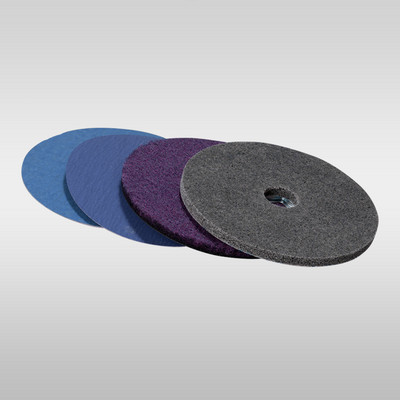

Die Krückemeyer GmbH ist einer der führenden Spezialisten für Schleifmittel und Klebebänder in Deutschland. Seit über 70 Jahren helfen wir unseren Kunden aus Industrie, Handel und Handwerk bei ihren Schleif- und Klebeanwendungen.

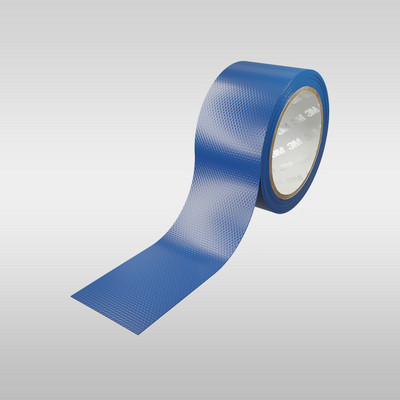

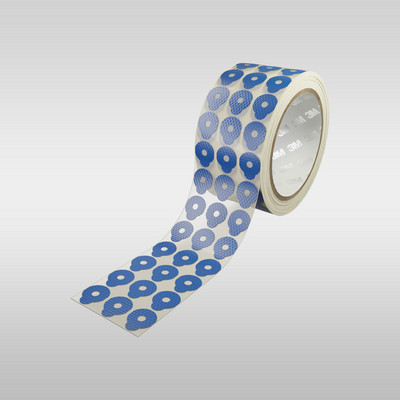

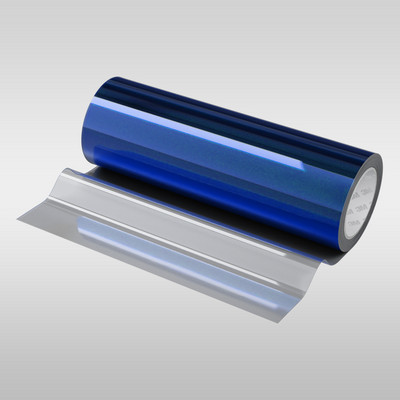

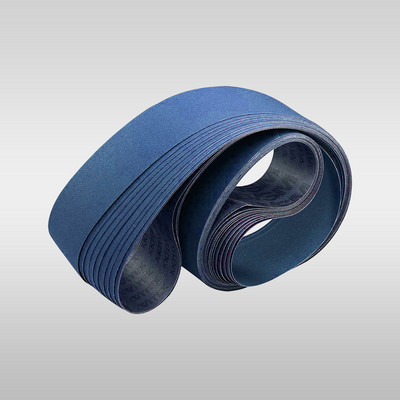

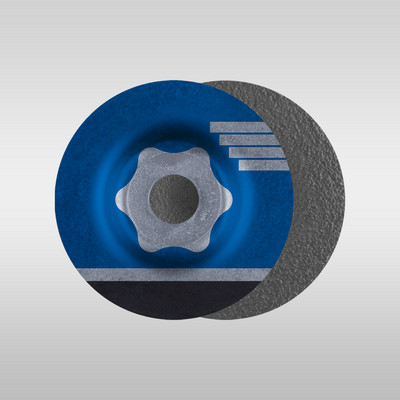

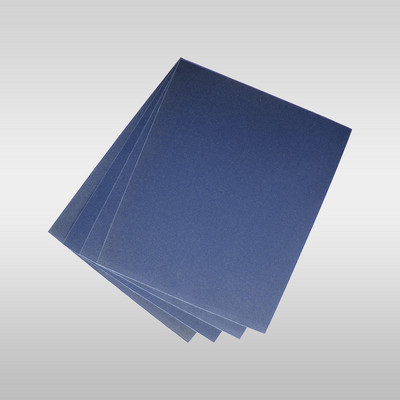

Wir fertigen und verarbeiten Schleif- und Klebebänder in höchster Qualität. Dabei bildet ein Schwerpunkt die Fertigung von individuellen Produktlösungen, wie z.B. Formstanzteile aus Klebebändern oder technischen Folien.